Chapter 9 Mechanical Properties Of Solids

CHAPTER NO.9 MECHANICAL PROPERTIES OF

SOLIDS

9.1 INTRODUCTION

In Chapter 7, we studied the rotation of the bodies

and then realised that the motion of a body depends on how mass is

distributed within the body. We restricted ourselvea

to simpler

stiuations of rigid bodies. A rigid body generally

means a hard solid object. having a definite shape and size. But tn

reality, bodica can be stretched, compressed and

bent. Even the appreciably rigid steel bar can be deformed when a sufficiently

large external force ts applied on tt. This means that solid bodies are not

perfectly rigid.

Asolid has defintte shape and size. In order to

change (or deform) the shape or size of a body, a force is required. If

you stretch a helical apring by gently pulling tts

ends, the length of the spring increases slightly. When you leave the ends of

the spring, it regains its original size and shape. The

property of a body, by virtue of which it tends to

regain its original size and shape when the applied force is removed, is known

as elasticity and the deformation caused is known as elastic deformation.

However, ifyou apply force to a lump of putty or mud, they have no groas

tendency to regain their

previous shape, and they get permanently deformed.

Such substances are called plastic and this property 1s called

Plasticity. Putty and muid are close to ideal

plastics.

The elastic behaviour of materials plays an

tmportant role in engineering design. For example, while designing a

building, knowledge of clastic properties of materials

Ifke steel,

concrete etc. is essential. The same ts true in the

design of bridges, automobiles, ropeways cic. One could alsa ask — Can we

design an aeroplane which is very light but sufficiently strong? Can we design

an artificial limb which is lighter but stronger? Why does a raflway track have

a particular shape like I? Why {a glass brittle while braas is not? Answers to

such questiona begin with the study of how relatively sfmple kinds of loads or

forces act to deform

different. solids bodies. In this chapter, we shall

study the elastic behaviour and mechanical properties of

solids which would anawer many such

questions.

9.2 ELASTIC BEHAVIOUR OF SOLIDS

We know that in a solid, each atom or molecule ie

surrounded by neighbouring atoms or molecules. These are bonded together by

interatomic or intermolecular forces and stay

in a stable equilforiun position. When a solid ts

deformed, the atoms or molecules are displaced from their equilibrium positions

causing a

change in the interatomic (or intermolecular)distances.

When the deforming force is removed, the interatomic forces tend to drive them

back to their original positions. Thus the body regains its original shape and

size. The restoring mechanism can be visualised by taking a model of spring-ball

system shown in the Fig. 9.1. Here

the balls represent atoms and springs represent

interatomic forces.

If you try to displace any ball from its

equilfbrium postition, the spring system trica to

restore the ball back to ite original poattion. Thus elastic behaviour of

solids can be explained in

terms of microscopic nature of the solid. Robert

Hooke, an English physicist (1635 - 1703 AD)performed experiments on springs

and found

that the elongation (change in the length)produced

in a body is proportional to the applied force or load. In 1676, he presented

his law of

elasticity, now called Hooke's law. We shall study

about ft in Section 9.4. This law, like Boyle's law, is one of the carliest

quantitattve relationships in science. It is very important to

know the behaviour of the materials under various

kinds of load from the context of engineering design.

8.3 STRESS AND STRAIN

When forces are applied on a bedy in such a manner that the body is still in static

equilibrium, it is deformed to a small or large extent depending upon the

nature of the material of the body and the magnitude of the deforming

force. The deformation may not be noticeable

visually in many materials but it is there. When a body is subjected to a

deforming force, a

restoring force is developed in the bedy. This

restoring force is equal in magnitude but opposite in direction to the applied

force. The restoring force per unit arca is known as strese.

If Fis the force applied and A is the area of cross

section of the body,

Magnitude of the stress = F/A 8.1)

The SI unit of stress is Nm? or pascal (Pa)and its

dimensional formula is | MLOT? J.There are three ways in which a solid may

change its dimensions when an external force acts on it. These are shown in

Fig. 9.2. In ig.9.2(a), a cytinder is stretched by two equal

forces applied nannal to its cross-sectional

area.The restoring force per unit area in this case is called tensile stress.

If the cylinder is compressed under the action of applied forces,the restoring

force per mit area is known as

compressive stress. Tensile or compressive stress

can alse be termed as longttudinal stress.In both the cases, there is a change

in the length of the cylinder. The change in the length

AL te the original length L of the body (cylinder in

this case) is known as longitudinal strain.

Longitudinal strain = = (9.2)

However, if two equal and opposite deforming forces

are applied parallel to the cross-sectional area of the cylinder, as shown in

Fig. 9.2(b),

there is relative displacement between the opposite

faces of the cylinder. The restoring force per unit area developed due to the

applied tangential force is known as tangential or shearing stresa.

Robert Hooke

(1635 - 1703 AD.)

Robert Hooke was born on July 18, 1635 in

Freshwater, Isle of Wight. He waa

one of the most brilliant and versatile seventeenth

century Engiah scientists. Ea cy 5 He attended Oxford University but never

graduated. Yet he was an extremely eee.talented inventor, instrument-maker and

building designer. He assisted Robert aA Boyle in the construction of Boylean

air pump. In 1862, he was appointed aa ad a

Curator of Expertments to the newly founded Royal

Society. In 1865, he became 5 = Profeascr of Geometry in Gresham College where

he carried out his astronomi- a Ree.cal observations. He built a Gregorian

reflecting telescope; diacovered the fifth ra » & star in the trapezium and

an aateriam in the constellation Orion; suggested that * H a Jupiter rotates on

ita axis; plotted detailed sketches of Mara which were later ra a ‘ay used in the

19 century to determine the planet’s rate of rotation; stated the ;inverse

square law to deacribe planetary motion, which Newton modified later etc. He

was elected Fellow of Royal Society and also served aa the Society's Secretary

from 1667 to 1682. In his series of observations presented in Micrographia, he

suggested

wave theory of Hght and first used the word ‘cell’

in a biological context as a result of his studies of cork.Robert Hooke is best

known toc physicists for his diacovery of law of elasticity: Ut teusio, sic vis

(This is a Latin expreasion and it means as the distortion, ao the force). Thin

law laid the basin for studies of streas and strain and for understanding the

elastic materials.As a result of appHed tangential force, there is a relative

displacement Ax between opposite

faces of the cylinder as shown in the Fig. 9.2(b).

The strain so produced is known as shearing etrain

and it is defined as the ratio of relative displacement of the faces Ax to the

length of the cylinder L.

AX

Shearing strain “FT = tan @ (9.3)

where @ is the angular displacement of the cylinder

from the vertical (original position of the cylinder}. Usually @ 1s very small,

tan @ is nearly equal to angle @, (if @= 10°, for example, there is only 1%

difference between 6

and tan @.It can also be visualised, when a book is

pressed with the hand and pushed horizontally,as shown in Fig. 9.2 (c}.

Thus, shearing strain = tan 8 = @ (9.4)

In Fig. 9.2 (d), a solid sphere placed in the fluid

under high pressure is compressed uniformly on all sides. The force appHed by

the fluid acts in perpendicular direction at each

point of the surface and the body is said to be

under hydraulic compression. This leads to decrease in its volume without any

change of its geometrical shape.

The body develops internal restoring forces that are

equal and opposite to the forces applied by the fluid (the body restores its

original shape

and size when taken out from the fluid). The internal restoring force per unit area in this

case is known as hydraulic stress

and in magnitude is equal to the hydraulic preasure (applied force

per unit area).

The strain produced by a hydraulic pressure is

called volume strain and is defined as the ratio of change in volume (AV) to

the original volume (V).

AV Volume strain = vy (9.5)Since the strain is a

ratio of change in

dimension to the original dimension, it has no units

or dimensional formula.

9.4 HOOKE’S LAW

Stress and strain take different forms in the

situations depicted in the Fig. (9.2). For small deformations the stress and

strain are proportional to each other. This is known as Hooke’s law.

Thus,stress strain

stress = k x strain (9.6)where k is the

proportionality constant and is

known as moduhus of elasticity.

Hooke’s law is an empirical law and is found to be

valid for most materials. However, there are some materials which do not

exhibit this linear relationship.

9.5 STRESS-STRAIN CURVE

The relation between the stress and the strain for a

given material under tensile stress can be found experimentally. In a standard

test of

tensile properties, a test cylinder or a wire is

stretched by an applied force. The fractional change in length {the strain) and

the applied force needed to cause the strain are recorded.The applied force is

gradually increased in steps and the change in length is noted. A graph is

plotted between the stress (which is equal in Magnitude to the applied force

per unit area)and the strain produced. A typical graph for a

metal is shown in Fig. 9.3. Analogous graphs for

compression and shear stress may also be obtained. The stress-strain curves

vary from material to material. These curves help us to understand how a given

material deforms with increasing loads. From the graph, we can see

that in the region between O to A, the curve is

linear. In this region, Hooke’s law is obeyed.

The body regains its original dimensions when the

applied force is removed. In this region, the solid behaves as an elastic body.

In the region from A to B, stress and strain are

not roportional.Nevertheless, the body

still

returns to its original dimension when the load is

removed. The point B in the curve is known as yield point (also known as

elastic limit) and the corresponding stress is known as yield

strength (c,) of the material.

If the load is increased further, the stress

developed exceeds the yield strength and strain increases rapidly even for a

amall change in the

stress. The portion of the curve between B and D

shows this. When the load is removed, say at some point C between B and D, the

body does not regain its original dimension. In this case,

even when the stress is zero, the strain is not

zero. The material is said to have a permanent set. The deformation is said to

be plastic deformation. The point D on the graph is the ultimate tensile

strength (c,) of the material.

Beyond this point, additional strain is produced

even by a reduced applied force and fracture occurs at point E. If the ultimate

strength and fracture points D and E are close, the material is said to be

brittle. If they are far apart, the

Material is said to be ductile.4s stated earlier,

the stress-strain behaviour

varies from material to material. For example,rubber

can be pulled to several times its original length and still returns to its

original shape.Fig. 9.4 shows stress-strain curve for the elastic tissue of

aorta, present in the heart. Note that although elastic region is very large,

the material does not obey Hooke’s law over most of the

region. Secondly, there is no well defined plastic

region. Substances like tissue of aorta, rubber etc. which can be stretched to

cause large strains

are called elastomers.

9.6 ELASTIC MODULI

The proportional region within the elastic limit of

the stress-strain curve (region OA in Fig. 9.3)is of great importance for

structural and

manufacturing engineering designs. The ratio

ofstress and strain, called modulus of elasticity,is found to be a

characteristic of the material.

9.6.1 Young's Modulus

Experimental observation show that for a given

material, the magnitude of the strain produced is same whether the stress is

tensile or compressive. The ratio of tensile (or compressive)

stress (0) to the longitudinal strain (@ is defined

as Young's modulus and is denoted by the symbol Y.0 Y= : @.7) From Eqs. (9.1)

and {9.2), we have Y=(F/A/(AL/D = (Fx D /(Ax AD) (2.8)

Since strain is a dimensionless quantity, the unit

of Young's modulus is the same as that of stress i.e., N nr® or Pascal (Pa).

Table 9.1 gives the values of Young's moduli and yield strengths of some

materials.

From the data given in Table 9.1, it ia noticed that

for metals Young's moduli are large.Therefore, these materials require a large

force to produce small change in length. To increase the length of a thin steel

wire of 0.1 cm? cross-

sectional area by 0.1%, a force of 2000 N is required.

The force required to produce the same strain in aluminium, brass and copper

wires having the same cross-sectional area are 690 N,

900 N and 1100 N respectively. It means that steel ie more elastic than copper, brass and aluminium. It is for this reason that steel is

preferred in heavy-duty machines and in structural designs. Wood,

bone, concrete and

glass have rather small Young's moduli.Example 9.1 Astructural steel rod has a

radius of 10 mm and a length of 1.0m. A 100 EN force stretches ft along its length.Calculate (a) stress, (b) elongation, and (c)strain on the rod. Young’s modulus, of structural steel is 2.0 x 1071 N m7.

Answer We assume that the rod ts held by a clamp at

one end, and the force F is applied at the other end, parallel] to the length

of the rod.Then the stress on the rod is given by

: FF

Sttess=— = Zz

A

~ 100x10°N

3.14x( 107 m}-

=3.18 x 10° N m?

The elongation,

apa ADL

Y

( 3.18x10°N m™? dm)

* 2x10'' Nm?

=1.59x 105m

= 1.59 mm

The strain is given by

Strain = AL/L

= (1.59 x 10° m)/{1m)

= 1.59x 105

= 0.16% <

Example 9.2 A copper wire of length 2.2

m and a steel wire of length 1.6m, both of diameter

3.0 mm, are connected end to end.When stretched by a load, the net

elongation is found to be 0.70 mm. Obtain the load

applied.

Answer The copper and steel wires are under a

tensile stress because they have the same tension (equal to the load W} and the

same area of cross-section A. From Eq. (9.7) we have stress = strain x Young's

modulus. Therefore W/A= Y,x (AL,/L) = Y, x (AL,/L)

where the subscripts c and s refer to copper and

stainless steel respectively. Or,AL JAL, = (Y,/Y) x W/L)Given L,= 2.2 m, L,=

1.6m,From Table 9.1 Y, = 1.1 x 10"! N.m®, and Y¥,=2.0x 10" N.m*.

AL/AL, = (2.0 x 10"./1.1 x 10") x

(2.2/1.6) = 2.5.The total elongation is given to be AL, + AL, = 7.0 x 10+m

Solving the above equations,AL,=5.0 x10¢m, and

AL,=2.0 x 104m.

Therefore Ws (Ax Y, x AL}/L,=n (1.5x 1057 x (6.0 x

104 x 1,1 x 10%) /2.2]

=1.8x10?N 4

Example 9.3 In a human pyramid in a

circus, the entire weight of the balanced group is supported by the legs of a

performer who is lying on his back (as shown in Fig. 9.5). The combined mass of

all the persons performing the act, and the

tabks, plaques etc. involved is 280 kg. The mass of

the performer lying on his back at the bottom of the pyramid is 60 kg. Each

thighbone (femur) of this performer has a length of 50 cm and an effective

radius of 2.0 cm. Determine the amount by which each thighbone gets compressed

under the extra load.

Answer Total maas of all the performers,

tables, plaques etc. = 280 kg Mass of the performer

= 60 kg Mass supported by the legs of the performer at the bottom of the

pyramid = 280 - 60 = 220 kg

Weight of this supported mass

= 220 kg wt. = 220 x 9.8 N = 2156 N.

Weight supported by each thighbone of the performer

= %4 (2156) N = 1078 N.

From Table 9.1, the Young's modulus for bone is

given by Y = 9.4x 10°Nm?,

Length of each thighbone L = 0.5 m

the radius of thighbone = 2.0 cm

Thus the cross-sectional area of the thighbone A =x

(2x 107)? m? = 1.26 x 10° m?.Using Eq. (9.8), the compression in each thighbone

(AJ) can be computed as

AL = [FxD/(x Al

= ((1078x0.5)/(9.4.x 10° x 1.26 x 10%]

= 4.55 x 105 m or 4.55 x 10° cm.

This is a very small change! The fractional decrease

in the thighbone is AL/L = 0.000091 or 0.0091%. <

9.6.2 Determination of Young's Modulus of the

Material of a Wire

Atypical experimental arrangement to determine the

Young's modulus ofa material of wire under tension is shown in Fig. 9.6. It

consists of two

long straight wires of same length and equal radius

suspended side by side from a fixed rigid support. The wire A {called the

reference wire)carries a millimetre main scale M and a pan to place a weight.

The wire B (called the

experimental wire) of uniform area of cross-section also

carries a pan in which known weights can be placed. A vernier scale V is

attached to a pointer at the bottom of the experimental wire B, and the main

scale M is fixed to the reference wire A. The weights placed

in the pan exert a downward force and stretch the

experimental wire under a tensile streas. The elongation of the wire (increase

in length) is measured by the vernier arrangement. The reference wire is used

to compensate for any

change in length that may occur due to change in

room temperature, since any change in length of the reference wire due to

temperature change will be accompanied by an equal change in

experimental wire. (We shall study these

temperature effects in detail in Chapter 11.)

Both the reference and experimental wires are given

an initial amall load to keep the wires straight and the vernier reading is

noted. Now the experimental wire is gradually loaded with

More weights to bring it under a tensile stress and

the vernier reading is noted again. The difference between two vernier readings

gives the elongation produced in the wire. Let rand L

be the initial radius and length of the

experimental wire, respectively. Then the areca of

cross-section of the wire would be ar*. Let M be the mass that produced an

elongation AL in the wire. Thus the applied force is equal to Mg,

where gis the acceleration due to gravity. From Eq.

(9.8), the Young’s modulus of the material of the experimental wire is given by

o Mg L

Veg Ter AL

= Mgx L/lar* x AD (9.9)

0.6.3 Shear Modulus

The ratio of shearing stress to the corresponding

shearing strain is called the shear modulus of the material and is represented

by G. It is also called the modulus of rigidity.

G = shearing stress (c,) /shearing strain

G = (F/A)/(Ax/1)

= (Fx D/{Ax AX (9.10)

Similarly, from Eq. (9.4)

G =(F/A/é

= F/(Ax 4 (9.11)

The shearing stress 6, can also be expressed as

= Gxe@ (9.12)

SI unit of shear modulus is N nr or Pa. The shear

moduli of a few common materials are given in Table 9.2. It can be seen that

shear modulus (or modulus of rigidity) is generally less

than Young's modulus (from Table 9.1). For most

materials G = Y/3.Table 9.2 Shear moduli (G} of some common

matorials

Exampie 9.4 A square lead slab of side 50 cm and

thickness 10 cm is subject to a shearing force (on its narrow face) of 9.0 x

104 N. The lower edge is riveted to the floor.

Answer The lead slab is fixed and the force is

applied parallel to the narrow face as shown in Fig. 9.7. The area of the face

parallel to which this force is applied is

A =50cmx 10cm

=0.5mx0.1m

= 0.05 m*

Therefore, the stress applied ts

= (9.4 x 10* N/0.05 m’)= 1.80 x 10° N.m?

‘We kmow that shearing strain = (Ax/L)= Stress

/G.Therefore the displacement Ax= (Stress x D/G = (1.8 x 10° N mr x 0.5m)/(5.6

x 10° N m4)=1.6x 104+ m=0.16 mm <

9.6.4 Bulk Modulus

In Section (9.3), we have seen that when a body is

submerged in a fluid, it undergoes a hydraulic stress (equal in magnitude to

the hydraulic pressure}. This leads to the decrease in the

volume of the body thus producing a strain called

volume strain [Eq. (9.5)]. The ratio of hydraulic stress to the corresponding

hydraulic strain is

called bulk modulus. It is denoted by symbol B.B=-

p/(AV/V) (9.13)

The negative sign indicates the fact that with an

increase in preasure, a decrease in volume occurs. That is, if p is positive,

AV is negative.Thus for a system in equilibrium, the value of

bulk modulus B is always positive. SI unit of bulk

modulus is the same as that of pressure te., N m? or Pa. The bulk moduli of a

few common materials are given in Table 9.3.

The reciprocal of the bulk modulus is called

compressibility and is denoted by k. It is defined as the fractional change in

volume per unit increase in pressure.k= (1/B =-(1/Ap) x (AV/Y) (9.14)

It can be seen from the data given in Table 9.3 that

the bulk moduli for aolids are much larger than for liquids, which are again

much larger than the bulk modulus for gases (air).

Thus solids are least compressible whereas gases are

most compressible. Gases are about a million times more compressible than

solids! Gases have

large compressthilities, which vary with pressure

and temperature. The incompreasibility of the solids is primarily due to the

tight coupling

between the neighbouring atoms. The molecules in

liquids are also bound with their neighbours but not as strong as in solids.

Molecules in gases are very poorly coupled to their neighbours.

Table 9.4 shows the various types of stress,strain,

elastic moduli, and the applicable state of matter at a glance.

Example 9.5 The average depth of Indian

Ocean is about 3000 m. Calculate the

fractional compression, AV/V, of water at the bottom

of the ocean, given that the bulk modulus of water is 2.2 x 10° N m~. (Take g

=10ms”)

Answer The pressure exerted bya 3000 m

column of water on the bottom layer

P=hpg =3000m x 1000 kgm*x 1lOms?

=3 x10’ kgm's =3 x10’Nm?

Fractional compression AV/Y, is

AV/V =stress/B =(3x10’Nur9)/Q.2x10°Nor4

=1.36x10%or 1.36% <4

9.7 APPLICATIONS OF ELASTIC BEHAVIOUR

OF MATERIALS

The elastic behaviour of materials plays an important

role in everyday life. All engineering deaigns require precise knowledge of the

elastic behaviour of materials. For example while designing a buflding. the

structural design of

the columns, beams and supports require

knowledge of strength of materials used. Have you

ever thought why the beams used in construction of bridges, as supports etc.

have a cross-section of the type I? Why does a heap of sand or a hill have a

pyramidal shape? Answers to these questions can be obtained from the

study of structural engineering which is based on

concepts developed here.

Cranes used for lifting and moving heavy loads from

one place to another have a thick metal rope to which the load is attached. The

rope is pulled up using pulleys and motors. Suppose we want

to make a crane, which has a lifting capacity of 10

tonnes or metric tons {1 metric ton = 1000 kg). How thick should the steel rope

be? We obviously want that the load does not deform the

rope permanently. Therefore, the extension should

not exceed the elastic limft. From Table 9.1, we find that mild steel has a

yield strength (S,) of about 300 x 16° N m®. Thus, the area of

cross-section (A) of the rope should at least be

A2W/S, = Mo/S, (9.15)

= (104 kgx 10 ms /(800 x 10°N m4)

= 3.3 x 104 m?

corresponding to a radius of about 1 cm for a rope

of circular cross-section. Generally a large margin of safety {of about a

factor of ten in the load) is provided. Thus a thicker rope of radius

about 3 cm is recommended. A single wire of thie

radius would practically be a rigid rod. So the ropes are always made of a

number of thin wires braided together, like in pigtails, for ease

in manufacture, flexibility and strength.

A bridge has to be designed such that it can

withstand the load of the flowing trafiic, the force of winds and its own

weight. Similarly, in the design of buildings use of beams and columns

is very common. In both the cases, the

overcoming of the problem of bending of beam under a

load is of prime importance. The beam should not bend too much or break. Let us

consider the case of a beam loaded at the centre and supported near ita ends as

shown in

Fig. 9.8. A bar of length 1, breadth b, and depth d

when loaded at the centre by a load W sagas by an

amount given by

&= WI? /(4bd*y) (9.16)

This relation can be derived using what you have

already learnt and a little calculus. From Eq. (8.16), we see that to reduce

the bending for a given load, one should use a material with a

large Young’s modulus Y. For a given

material,increasing the depth d rather than the breadth bis more efiective in

reducing the bending, since 6 is proportional to d~* and only to b (of course

the length i of the span should be as amall as possible). But on increasing the

depth, unless the load is exactly at the right place (difficult to

arrange in a bridge with moving traffic), the deep

bar may bend as shown in Fig. 9.9(b). This is called buckling. To avoid this, a

common compromise is the cross-sectional shape shown

in Fig. 8.9(c). This section provides a large

load-bearing surface and enough depth to prevent bending. This shape reduces

the weight of the beam without sacrificing the strength and hence

reduces the cost.

Use of pillars or columns is also very common.in

buikiings and bridges. A pillar with rounded ends as shown in Fig, 9.10{a)

supports less load

than that with a distributed shape at the ends Fig.

9.10(b)]. The precise design of a bridge or a building has to take into account

the conditions under which it will fimction, the cost and long period,

reliability of usable

materials etc.

The answer to the question why the maximum height of

a mountain on earth is ~10 kan can also be provided by considering the elastic

properties of rocks. A mountain base is not

under uniform compression and this provides some

shearing stress to the rocks under which they can flow. The stress due to all

the material

on the top should be less than the critical shearing

stress at which the rocks flow.

At the bottom of a mountain of height h, the force

per unit area due to the weight of the Mountain is fpg where p is the density

of the material of the mountain and g is the acceleration due to gravity. The

material at the

bottom experiences this force in the vertical

direction, and the sides of the mountain are free.Therefore this ia not a case

of pressure or buik compression. There is a shear component,approximately hpg

itself. Now the elastic limit

for a typical rock is 30 x 10’ N m®, Equating this

to hpg, with p = 3 x 10° kg mm gives

hpg =30x 10’ Nm. Or

nh = 30x10 Nm?/8x 10 kgm*>x10ms4

=10kn

which is more than the height of Mt. Evereatt

SUMMARY

1. Streseis the restoring force per unit area and

strain is the fractional change in dimension.In general there are three types

of streasea (a) tenaile strese — longitudinal atreas (associated with

stretching) or compressive streas (associated with compression),(b) shearing

atresa, and (c) hydraulic stress.

2. For amall deformations, streaa is directly

proportional to the strain for many materials.This is known as Hooke's law. The

constant of proportionality is called modulus of dasticity. Three elastic

moduli viz., Young's modulus, shear modulus and bulk modulus

are used to describe the elastic behaviour of

objects as they respond te deforming forces that act on them.

Aclase of solids called elastomers does not obey

Hooke’a law.

3. When an object is under tension or compreseion,

the Hooke's law takes the form F/A = YAL/L where AL/Lis the tenaile or

compressive strain of the object, F ia the magnitude of the

applied force causing the strain, A is the cross-sectional

area over which F is applied (perpendicular to A) and Yis the Young's modulus

for the object. The stress is F/A.

4. Apalr of forces when applied parallel to the

upper and lower faces, the solid deforms so thet the upper face moves sideways

with respect to the lower. The horizontal displacement AL of the upper face is

perpendicular to the vertical height L, This type of deformation is called

shear and the corresponding stress ie the shearing stress. This

type of atrese is poeaible only in solids,In this

kind of deformation the Hooke's law takea the form F/A = Gx AL/L where AL is

the displacement of one end of object in the direction of the applied force

F,and Gis the ahear modulus.

5. When an object undergoes hydraulic compression

due to a stress exerted by a

surrounding fluid, the Hooke’s law takes the form

p=B(av/v,where p is the pressure (hydraulic stress) on the object due to the

fhiid, AV/V {the

volume strain) is the absolute fractional change in

the object's volume due to that pressure and B 1s the bulk moduhus of the

object.

POINTS TO PONDER

1. In the case of a wire, suspended from celing and

stretched under the action of a weight (F) suspended from fta other end, the

force exerted by the ceiling on tt ia equal and opposite to the weight However,

the tension at arry cross-section A of the wire is just F

and not 2F. Hence, tenaile streas which is equal to

the tension per unit arca ia equal to F/A.

2. Hooke's law ia valid only in the Hncar part of

stress-strain curve.

3. The Young’s modulus and shear moduhis are

relevant only for solids since only solids have lengths and shapes.

4. Bulk modulus is relevant for solids, hquid and

gases. It refers to the change in vohime when every part of the body ie under

the uniform streas so that the ahape of the body remains unchanged.

5. Metals have larger valucs of Young's modulus than

alloys and dastomers. A material with lerge value of Young's mnodulus requires

a large force to produce small changes in ita length.

6. In daily life, we feel that a material which

stretches more is more elaatic, but it a ia misnomer. In fact material which

stretches to a leaser extent for a given load is considered

to be more clastic.

7. In general. a deforming force in one direction

can produce strains in other directions also. The proportionality between

stress and strain tn such situations cannot be described

by just one elastic constant. For example, for a

wire under longitudinal strain. the lateral dimensions (radius of cross

section) will undergo a amall change, which ia described by another elastic

constant of the materia) {called Poisson mito).

8. Stress is not a vector quantity simce, unlike a

force, the streas cannot be assigned a spectfic direction. Force acting on the

portion of a body on a specified aide of a section haa a defintts direction.

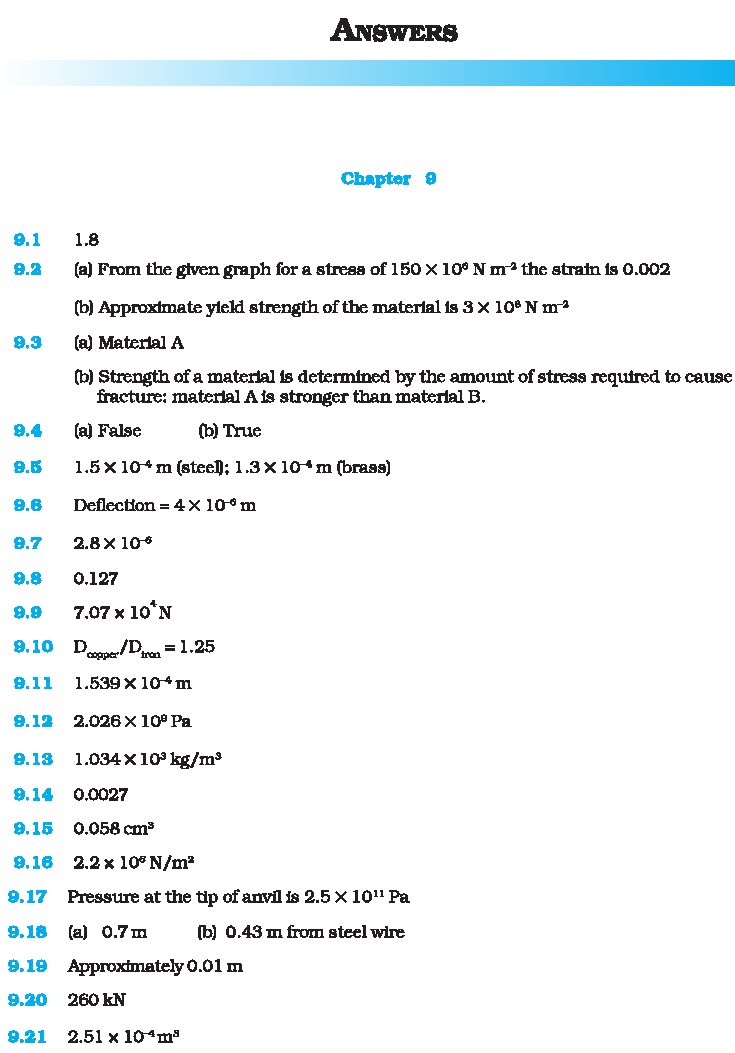

EXERCISES

9.1 A steel wire of length 4.7 m and crosa-sectional

area 3.0 x 10% m? stretches by the same amount as a copper wire of length 3.5 m

and crosa-sectional area of 4.0 x 10% m under a given load. What is the ratio

of the Young’s modulus of steel to that of copper?

9.2 Figure 9.11 shows the strain-strese curve for a

given material. What are (a) Young's modulus and {b) approximate yield strength

for this material?

9.3 The stresa-strain graphs for materials A and B

are ahown in Fig. 9.12.‘The graphe are drawn to the same scale.

(a) Which of the materials has the greater Young's

modulus?

(b} Which of the two fs the stronger material?

9.4 Read the following two statements below

carefully and state, with reasons, if it is true or false.

(a) The Young's modulus of rubber is greater than

that of steel;

(b} The stretching of a cofl is determined by its

shear modulus.

9.8 Two wires of diameter 0.25 cm, one made of steel

and the other made of brass are loaded as shown in Fig. 9.13. The unloaded

length of steel wire is 1.5 m and that of brags wire is 1.0 m. Compute the

elongationa of the steel and the brass wires.

9.8 The edge of an ahunintum cube is 10 cm long. One

face of the cube is firmly fixed to a vertical wall. A mass of 100 kg is then

attached to the opposite face of the cube. The shear modulus of aluminium is 25

GPa. What is the vertical deflection of this face?

8.7 Four identical hollow cylindrical columns of

mild steel support a big structure of mase 50,000 kg. The inner and outer radti

of each column are 30 and 60 an respectively.Assuming the load distribution to

be uniform, calculate the compressional strain of each column.

9.8 Apiece of copper having a rectangular

crose-section of 15.2 mm x 19.1 mm js pulled in tension with 44,500 N force,

producing only elastic deformation. Calculate the resulting

strain?

9.8 Asteel cable with a radius of 1.5 cm supports a

chairlift at a ski area. If the maximum atrese is not to exceed 10° N mm, what

is the maximum load the cable can support 7

9.10 A rigid bar of mass 15 kg is supported

symmetrically by three wires each 2.0 m long.Those at each end are of copper

and the middle one is of iron. Determine the ratios of their diameters if each

is to have the same tension.

9.11 A 14.5 kg masa, fastened to the end of a steel

wire of unstretched length 1.0 m, is whirled in a vertical circle with an

angular velocity of 2 rev/s at the bottom of the circle.The cross-sectional

area of the wire is 0.065 cm?. Calculate the elongation of the wire

when the maas is at the lowest point of ite path.

9.12 Compute the bulk modulus of water from the

following data: Initial vohime = 100.0 litre, Pressure increase = 100.0 atm (1

atm = 1.013 x 10° Pa), Final volume = 100.5 litre. Compare the bulk modulus of

water with that of air (at constant temperature).Explain in simple teams why

the ratio ia so large.

9.13 What is the density of water at a depth

where pressure is 80.0 atm, given that

ite density at the surface ia 1.03 x 103 kg m™°?

9.14 Compute the fractional change in volume of a

glass alab, when subjected to a hydraulic pressure of 10 atm.

9.18 Determine the volume contraction of a solid

copper cube, 10 am on an edge, when subjected to a hydraulic pressure of 7.0 x

10° Pa.

9.18 How much should the pressure on a litre of

water be changed to compress it by 0.10%?

Additional Exercises

9.17 Anvils made of single crystals of diamond, with

the shape as shown in

Fig. 9.14, are used to investigate behaviour of

materials under very high pressures.Flat faces at the narrow end of the anvil

have a diameter of 0.50 mm, and the wide ends are subjected to a compressional

force of 50,000 N. What is the pressure at the tip of the anvil?

9.18 A rod of length 1.05 m having negligible mass

is supported at its ends by two wircs of steel (wire A) and aluminium (wire B)

of equal lengthe as shown in Fig. 9.15. The cross-sectional areas of wires A

and B are 1.0 mm? and 2.0 mm’,respectively. At what point along the rod should

a mass m be suspended in order to produce (a) equal stresecs and (b) cqual

strains in both steel and aluminium wires.

9.19 A mild steel wire of length 1.0 m and

cross-sectional area 0.50 x 10% cm? is stretched, well within its elastic

limit, horizontally between two pillars. A maes of 100 g is suspended from the

mid-point of the wire. Calculate the depression at the mid-point.

9.20 Two strips of metal are riveted together at

their ends by four rivets, cach of diameter 6.0 mm. What is the maximum tension

that can be exerted by the riveted strip if the shearing etrees on the rivet is

not to exceed 6.9 x 10’ Pa? Assume that each rivet is to

carry one quarter of the load.

9.21 The Marina trench is located in the Pacific

Ocean, and at one place it ie nearly eleven kan beneath the surface of water.

The water pressure at the bottom of the trench is about 1.1 x 10° Pa. A steel

ball of initial volume 0.32 m* is dropped into the ocean and falls to the

bottom of the trench. What ie the change in the volume of the ball when it

reaches to the bottom?